A Comprehensive Overview to Examining Chemical Products for Optimum Integrated Solutions in Production and Beyond

In the significantly complex landscape of manufacturing, the evaluation of chemical products stands as a critical variable in attaining integrated options that focus on safety, effectiveness, and sustainability. This thorough overview details vital facets such as regulatory compliance, product compatibility, and cost-effectiveness, all while emphasizing the relevance of ecological stewardship.

Understanding Regulative Conformity

In the world of production, understanding regulatory compliance is critical for making sure both item safety and environmental protection. Regulative frameworks, such as the Occupational Safety and Health Administration (OSHA) criteria and the Environmental Defense Firm (EPA) guidelines, dictate the secure handling, storage space, and disposal of chemical items. Conformity with these laws not just safeguards employees but also minimizes ecological influence and boosts a business's online reputation.

Makers need to faithfully examine the chemical substances they utilize, ensuring adherence to the pertinent security data sheets (SDS) and labeling needs, which offer important details relating to risks and safe use. In addition, remaining abreast of industry-specific guidelines, such as the Enrollment, Examination, Authorisation and Limitation of Chemicals (REACH) in Europe, is crucial for keeping compliance and avoiding possible lawful ramifications.

Normal audits and training are important elements of a detailed compliance method, cultivating a society of safety and awareness among staff members. By prioritizing regulatory conformity, manufacturers can reduce risk, boost functional performance, and add to lasting techniques within the sector, inevitably bring about boosted item top quality and consumer contentment.

Assessing Product Compatibility

Regulatory compliance establishes the structure for safe manufacturing practices, yet examining product compatibility is equally vital for functional effectiveness and security. Chemical Products. Item compatibility describes the capability of different chemical materials to coexist without adverse interactions that can endanger the honesty of procedures or products. An extensive analysis begins with recognizing the chemical residential or commercial properties, consisting of reactivity, solubility, and security under different problems

Manufacturers need to carry out compatibility screening to recognize potential responses that might take place when chemicals are combined or enter contact with each other. This consists of examining variables such as temperature variations, stress modifications, and the presence of pollutants. It is additionally important to consider the effects of materials made use of in containers, pipes, and equipment, as these can influence chemical habits and performance.

Additionally, producers need to examine the prospective effect of item compatibility on end-user applications. Incompatible products can result in functional disturbances, item failings, and security dangers, which can harm reputation and financial standing. An organized method to evaluating item compatibility not only enhances operational effectiveness yet also makes certain the security and dependability of chemical items throughout their lifecycle.

Examining Cost-Effectiveness

Assessing cost-effectiveness is vital for suppliers aiming to enhance their chemical production processes while maintaining profitability. This evaluation starts with a thorough analysis of both straight and indirect prices connected with chemical products. Direct prices encompass the acquisition rate of chemicals, transport, and storage, while indirect prices may consist of labor, upkeep, and overhead costs.

To properly evaluate cost-effectiveness, manufacturers must utilize a complete price of possession (TCO) technique. This technique makes it possible for a comprehensive understanding of all expenses throughout the item lifecycle, from purchase to disposal. In addition, making use of performance metrics-- such as yield prices and process efficiency-- can offer understandings right into exactly how well chemical items add to general production goals.

Benchmarking versus market criteria can additionally highlight prospective locations for expense reduction or renovation. By comparing their prices and efficiency with competitors, manufacturers can recognize finest techniques and ingenious services.

Furthermore, involving distributors in discussions concerning prices, volume price cuts, and long-term contracts may generate positive monetary setups. Ultimately, a calculated emphasis on cost-effectiveness supports not only profitability yet additionally sustainability in the competitive landscape of chemical manufacturing.

Analyzing Environmental Effect

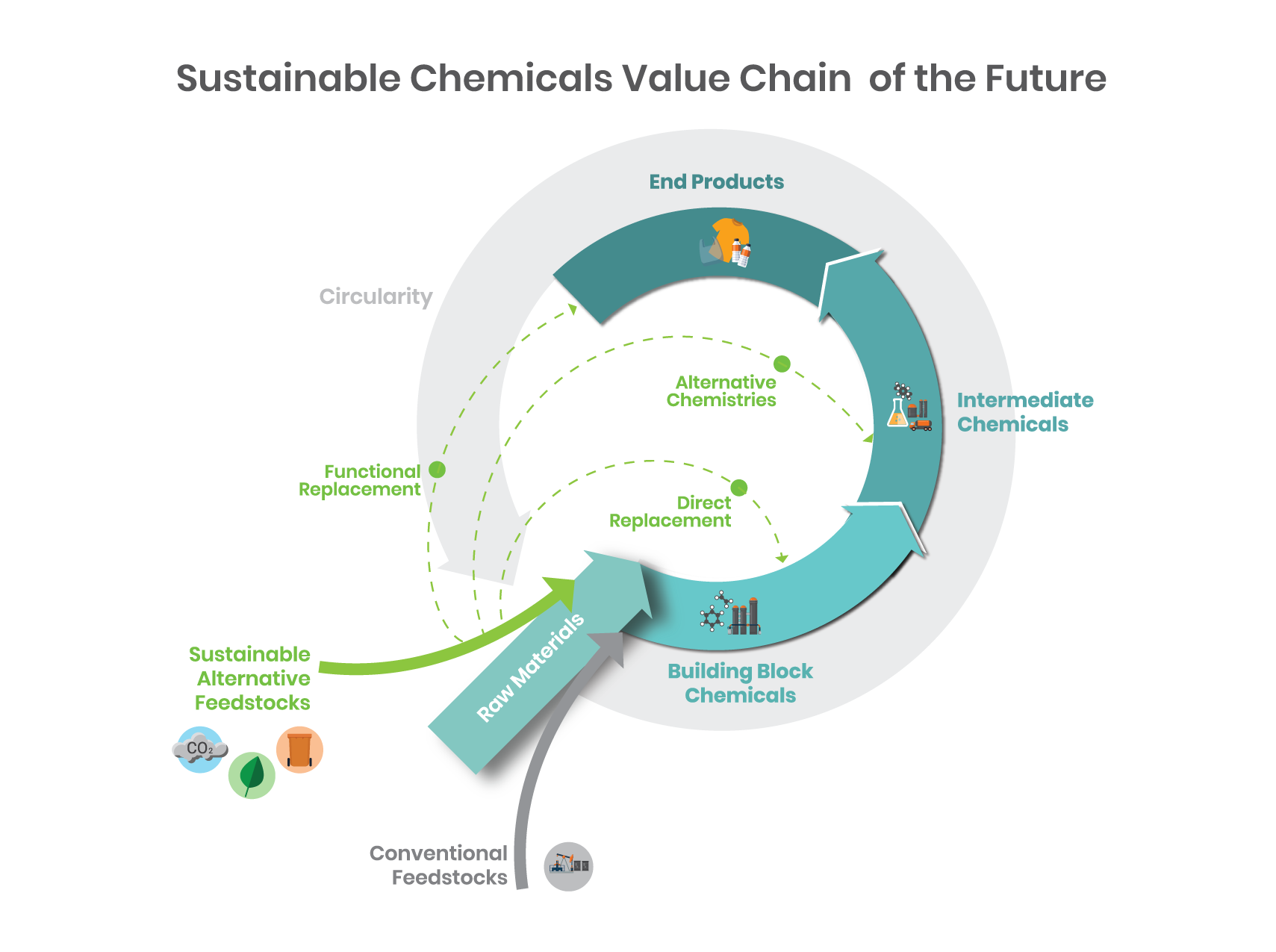

One vital facet is the option of resources. Lasting sourcing can significantly decrease adverse effects, as renewable or much less unsafe products usually result in reduce discharges and fewer harmful byproducts. Furthermore, suppliers must consider the effectiveness of their production procedures; maximizing these can lessen waste and energy consumption.

In addition, product solution plays a crucial role in identifying ecological safety. Making use of eco-friendly chemistry concepts can bring about the advancement of more secure, much less polluting choices. Producers must additionally evaluate end-of-life circumstances for their products, promoting recycling or risk-free disposal techniques to reduce lasting ecological effects.

Incorporating these considerations right into item examination not only enhances corporate obligation however additionally aligns with enhancing consumer demand for eco-friendly products. Chemical Products. Ultimately, a comprehensive evaluation of environmental effect is link crucial for fostering sustainable production techniques

Implementing Top Quality Control Actions

The commitment to sustainable techniques and environmental safety and security normally extends to the execution of quality assurance steps within making processes. Quality control is essential for making certain that chemical products fulfill predefined standards and laws, consequently protecting not just product effectiveness yet likewise ecological honesty.

To successfully implement quality assurance actions, producers need to take on a methodical strategy, beginning with the establishment of clear quality criteria. This consists of specifying requirements for basic materials, intermediate items, and final learn this here now results. Regular testing and examination protocols must be set up to monitor compliance with these benchmarks throughout the production cycle.

Training and involving staff in quality guarantee practices is just as critical. A well-informed workforce contributes to a society of high quality and liability, boosting general operational efficiency. Ultimately, rigorous quality assurance determines not only guarantee compliance but additionally strengthen the brand name's reputation and foster trust among consumers, straightening with the overarching objectives of sustainability and safety and security in the chemical production market.

Verdict

To conclude, the examination of chemical products demands a comprehensive understanding of regulatory conformity, item compatibility, cost-effectiveness, and Discover More environmental impact. Carrying out robust top quality control determines further enhances operational integrity and development within making procedures. By taking on a comprehensive technique, organizations can enhance chemical application, reduce linked risks, and straighten with industry finest techniques, ultimately promoting lasting growth. This guide acts as a vital source for attaining these critical objectives in chemical product examination.

Comments on “Discover the most recent Developments in Chemical Products for Enhanced Efficiency”